-Top mounted eccentric hemispherical valve

-Forged steel floating ball valve

-Forged steel floating ball valve

-Forged steel fixed ball valve

-Side mounted eccentric hemispherical valve

-Side mounted eccentric hemispherical valve

-High performance all welded pipeline ball valve

-American Standard floating ball valve

-American standard fixed ball valve

-American Standard forged steel floating ball valve

-American Standard forged steel floating ball valve

-Wafer type hard seal butterfly valve

-Automatic regulating butterfly valve

-Heavy hammer hydraulic control slow closing check butterfly valve

-Energy storage hydraulic control slow closing check butterfly valve

-Three eccentric flange hard seal butterfly valve

-Stainless steel quick installation butterfly valve

-Stainless steel threaded butterfly valve

-Stainless steel threaded butterfly valve

-ZZVP Self operated micro pressure regulating valve

-ZZWP Self operated temperature regulating valve

-ZZWPE Self operated electronic temperature control valve

-HTS Pneumatic diaphragm regulating valve

-ZMAX Pneumatic diaphragm high pressure angle regulating valve

-ZJHM Pneumatic sleeve regulating valve

-ZMAX Pneumatic diaphragm three-way regulating valve

-ZSHV Pneumatic V-shaped regulating ball valve

-ZJHP Pneumatic diaphragm regulating valve

-CV3000 Pneumatic diaphragm regulating valve

-T661Y Pneumatic feed water regulating valve

-ZDSJ Electric high pressure angle regulating valve

-ZDLQ、X Electronic electric three-way regulating valve

-ZAZP Electric single seat regulating valve

-ZDLM Electronic electric sleeve regulating valve

-ZDLM Electronic electric sleeve regulating valve

-ZDLN Electric two seat regulating valve

-T961Y Electric multi-stage regulating valve

-ZDLPF46 Electric fluorine plastic lined single seat regulating valve

-ZJHPF46 Pneumatic film lined fluorine single seat regulating valve

-ZSHO Start shut-off ball valve

-ZSHW Pneumatic regulating butterfly valve

Your location:Home - Product - Regulating valves

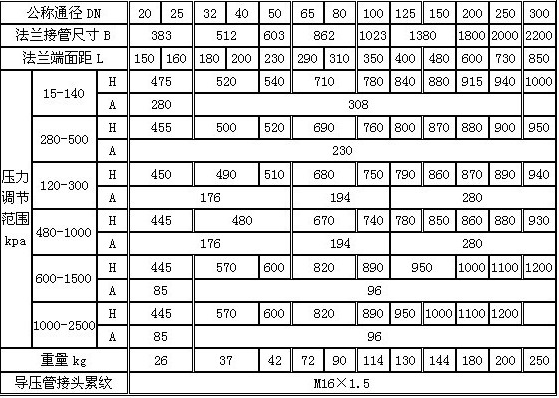

Nominal diameterDN20~DN300

Nominal pressurePN16、40、64

Connection formFlange

Flange formCasting method BG9113-88、JB/79-94

Product overview

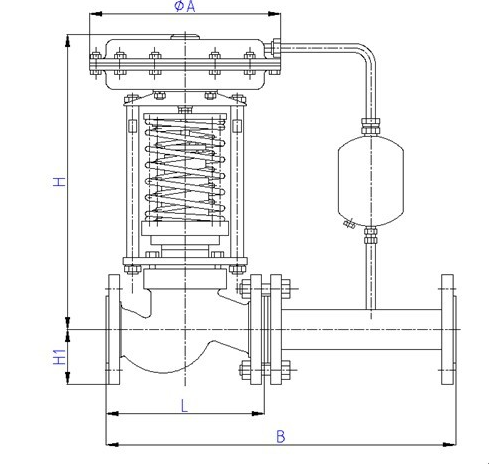

This series of products have three structures: single seat (zzyp), sleeve (zzym), double (zzyn) and; There are two kinds of actuators: diaphragm type and piston type; The function types include pressure regulation behind the pressure reducing valve (type b) and pressure regulation before the pressure relief valve (type K). The nominal pressure grades of products are PN16, 40 and 64; The diameter range of valve body is DN20 ~ 300; There are three levels of leakage: Level II, level IV and level VI; The flow characteristic is fast opening; The pressure is adjusted in sections from 15 to 2500 kPa. It can be combined as required to meet the working conditions of users.

Product parameters

The self operated pressure regulating valve does not need additional energy and can work in a place without electricity and gas, which is convenient and saves energy. The range of pressure sections is fine and cross each other, and the adjustment accuracy is high. The pressure setting value can be set continuously during operation. For the pressure regulation behind the valve, the ratio of the pressure before the valve to the pressure behind the valve can be 10:1 ~ 10:8. Rubber diaphragm detection, high measurement accuracy and sensitive action of actuator. The pressure balance mechanism is adopted to make the control valve sensitive and accurate.

Material of main parts

Main part materials: valve body: zg230-450, zg1cr18ni9ti, zgcr18ni12mo2ti

Valve core: 1Cr18Ni9Ti, Cr18Ni12Mo2Ti

Valve seat: 1Cr18Ni9Ti, Cr18Ni12Mo2Ti

Valve stem: 1Cr18Ni9Ti, Cr18Ni12Mo2Ti

Membrane cover: A3, A3 steel coated with tetrafluoroethylene stainless steel

Filler: nitrile, Yibing, fluorine, oil resistant rubber

Flange standard: casting method according to bg9113-88 and JB / 79-94

Flange sealing surface type: PN16 convex

PN40 and 64 are concave convex, and the valve body is concave

The structural length is as per bg12221-98

Actuator signal interface: internal thread M16 × one point five

※ the distance between valve body flange and flange end face can be manufactured according to the standard specified by the user. Such as ANSI, JIS, DIN, etc.