-Top mounted eccentric hemispherical valve

-Forged steel floating ball valve

-Forged steel floating ball valve

-Forged steel fixed ball valve

-Side mounted eccentric hemispherical valve

-Side mounted eccentric hemispherical valve

-High performance all welded pipeline ball valve

-American Standard floating ball valve

-American standard fixed ball valve

-American Standard forged steel floating ball valve

-American Standard forged steel floating ball valve

-Wafer type hard seal butterfly valve

-Automatic regulating butterfly valve

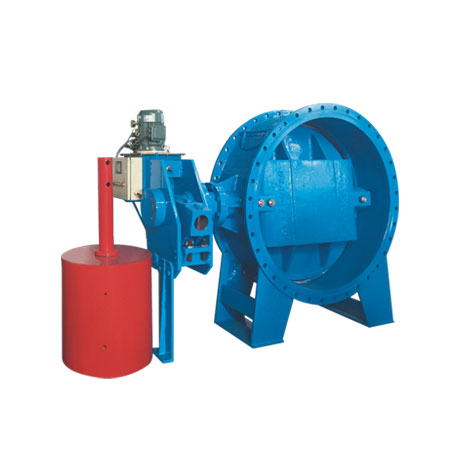

-Heavy hammer hydraulic control slow closing check butterfly valve

-Energy storage hydraulic control slow closing check butterfly valve

-Three eccentric flange hard seal butterfly valve

-Stainless steel quick installation butterfly valve

-Stainless steel threaded butterfly valve

-Stainless steel threaded butterfly valve

-ZZVP Self operated micro pressure regulating valve

-ZZWP Self operated temperature regulating valve

-ZZWPE Self operated electronic temperature control valve

-HTS Pneumatic diaphragm regulating valve

-ZMAX Pneumatic diaphragm high pressure angle regulating valve

-ZJHM Pneumatic sleeve regulating valve

-ZMAX Pneumatic diaphragm three-way regulating valve

-ZSHV Pneumatic V-shaped regulating ball valve

-ZJHP Pneumatic diaphragm regulating valve

-CV3000 Pneumatic diaphragm regulating valve

-T661Y Pneumatic feed water regulating valve

-ZDSJ Electric high pressure angle regulating valve

-ZDLQ、X Electronic electric three-way regulating valve

-ZAZP Electric single seat regulating valve

-ZDLM Electronic electric sleeve regulating valve

-ZDLM Electronic electric sleeve regulating valve

-ZDLN Electric two seat regulating valve

-T961Y Electric multi-stage regulating valve

-ZDLPF46 Electric fluorine plastic lined single seat regulating valve

-ZJHPF46 Pneumatic film lined fluorine single seat regulating valve

-ZSHO Start shut-off ball valve

-ZSHW Pneumatic regulating butterfly valve

Your location:Home - Product - Hydraulic valves

Nominal diameterDN50-DN400

Test shell strength1.0MPa~1.6MPa

Opening pressure≤0.03MPa

Local head loss≤0.03MPa

Body materialDuctile iron/stainless steel

Temperature≤80℃

Product overview

LHS745X online maintenance low resistance backflow preventer integrates multiple functions. In addition to ultra-low resistance and more reliable safety performance, the valve body is designed with expansion joint device and filter screen device, which shortens the overall length and size of installation, reduces the installation volume, and brings great convenience and benefits to customers. LHS745X low resistance backflow preventer is an on-line maintenance low resistance backflow preventer. The inlet is equipped with filter screen and telescopic flange. It uses the principle of hydraulic control valve and adopts a completely different control mode from the pressure reducing backflow preventer, which can not only ensure the level of isolation safety in the form of air isolation, but also effectively reduce the head loss. When the flow velocity v = 2.5m/s, the head loss H = 2~3M; It basically meets the requirements of the ideal backflow preventer. It is mainly used for effective isolation between urban water supply pipe network and various user pipe networks, or between domestic drinking water and heterogeneous water systems such as reclaimed water, fire water, air conditioning water and greening water, or supporting installation of non negative pressure equipment, which can strictly prevent backflow pollution.

Product features

1. Ultra low water loss and significant energy saving: at the economic flow rate (flow rate of 2m/s), the head loss is less than 3m;

2. Air isolation and automatic drainage: when the main valve is closed, the drainer opens automatically and the pressure relief in the middle chamber is zero. Air isolation or zero pressure isolation is realized between the upstream and downstream of the main valve, and the isolation performance is safe and reliable.

3. Saving land, materials and flexible installation: small appearance and light self weight. The valve is equipped with filter screen and expansion joint, and the structural length is only 30% of the existing similar products.

4. Easy maintenance and automatic alarm: no special pressure detector is required for detection, and automatic water leakage alarm can be configured.

Commissioning steps

Before the formal installation of the backflow preventer, all pipelines shall be thoroughly flushed to eliminate other irrelevant troubles. After installation and initial start-up, it is necessary to follow the following steps: close the outlet gate valve, slowly open the inlet gate valve, slowly fill the valve cavity with main water, and open each test ball to remove the air in the valve cavity, After the valve chamber is filled with water, slowly open the outlet gate valve to let the water fill the whole pipeline.

Working principle

Positive water supply: when the inlet pressure is greater than the outlet pressure, the two check valve discs are opened and the drainer is closed. At the flow rate of 2m/s, the circulating water loss is less than 0.04MPa

Reverse closing: when the inlet pressure is less than or equal to the outlet pressure, the two check valve discs are closed and the drain is opened.

If there is no garbage jam, the two check valve discs are sealed and closed, the outlet of the drainer is not drained, the middle chamber is connected with the atmosphere, and the pressure of the middle chamber is zero.

Prevent backflow pollution: when the inlet pressure is less than the outlet pressure, the two check discs are closed and the drainer is open. If one or two check discs

The valve port is blocked by garbage, resulting in leakage. The leaked medium flows to the middle chamber and is directly discharged out of the valve through the drain to prevent backflow pollution to the inlet end.

Product type

1. Built in drainage type low resistance backflow preventer DN≤50 threaded connection is divided into LHS711X type DN15-DN25 lhs712X type DN32-DN50

Among them, LHS711X product has no ball valve and imported filter screen

2. Flange connection model of DC low resistance backflow preventer: LHS743X DN50-DN200

3. Flange connection model of on-line maintenance low resistance backflow preventer: LHS745X DN150-DN400